Forever Flight Worldwide Took on the Challenge of Designing a Sustainable Air Traffic Control Tower

Design Concept Statement

01.18.2022

With the urgency of the climate crisis, our tower design keeps in mind the adverse effects of the construction process to limit environmental effects throughout its entire lifecycle. When designing with the environment as the priority, many upkeep costs are diminished, and the environment is less negatively impacted. Our innovative design utilizes the most sustainable building materials on the market to date; hempcrete and an algae facade system. Our initial analysis determined that with new sustainable materials, our ATCT would cost around $5,000,000-$6,000,000 excluding site excavation.

The foundation of our design arises from a minimalist approach. Our design of ATC Tower is not a first of its kind but a well thought and innovative approach towards reducing the negative impact of the structure and safeguarding the environment. The idea is to lower the resources needed to make it both cost-effective and environmentally smart while making our design aesthetically pleasing. This is achieved by lowering the footprint of the tower. Resource extraction of any kind is a destructive process for earth. Also designing with fewer materials will cost less. There is no need to design a tower that uses additional floors, rooms, or man-made materials. With a simple design, our tower is modular and prefabricated in sustainable materials.

The next generation of ATCT controlled towers must be equipped to deal with the challenges of the modern era. Two of the challenges our design finds solutions are cybersecurity and climate change. The Department of the Interior and Defense have declared the climate threat as extremely significant. Our designs take on these challenges by being developed with a cybersecurity plan and a lifecycle that emits as little carbon as possible.

The possible solution is to equip the ATCT with its own renewable energy. Based on our research, it is dangerous and not cost-effective to use solar panels emanating glare from the top. It is more cost-effective to equip ATCT connected to the local grid for its energy. If the ATCT’s power is sourced from local renewable energy plants, our design’s Scope 1 carbon emissions while in use would be zero.

Sustainability as the main focus, the tower is designed to be self sustained. With the immediate effects of the carbon pollution already being felt in all 50 states, our design attempts to reduce the amount of CO2 and additional pollutants from the ATCT, in construction phase, to the daily energy use and eventual recycling. Carbon emissions during construction can be controlled with prefabricated materials produced off-site. Since the designs are to be built in every community across the Union, the modular steel design will be produced locally, and off-site to reduce the carbon footprint. Limiting transportation externalities to minimize the various industrial pollutants. It is best for the health and prosperity of our airport communities to minimize the various industrial pollutants.

For the exterior of our ATCT, we designed with the most-sustainable material on the market. Our team identified hempcrete as the most effective material on the market to build the exterior of the ATCT shaft. This is not a new material, in fact, hempcrete was used by ancient civilizations to build large structures. It was used in Ancient Rome and now in contemporary North Carolina to build homes. Our design utilizes it to build the exterior of our ATCT shaft. The substance is underutilized, but just like any other resource, it has pros and cons. It has a high level of natural heat retention and reflection. This limits the amount of exterior electricity needed to heat and cool the interior of our ATCT. It is not nearly as strong as concrete, and has a 1 MPa. This is low compared to concrete, but our design does not use the hempcrete for support. The hempcrete in our tower is used for insulation and cladding. This eliminates the need for siding and costly insulation. Instead of perpetually destroying our environment resource extraction industry, our design supports resource development and rural economies through resources made from life.

Currently hempcrete is being used for homes and in some circumstances commercial applications. Research has indicated that finished hempcrete is actually carbon-negative- meaning the material continues to absorb CO2 after installation. The hemp plant needed for the material also absorbs CO2 while growing. Our design execution statement has more information on the benefits of hempcrete to the local economy.

The foundation is formed by piles and a foundation slab (40’ x 40’). Together these two structures form the foundation of the tower. Depending on the soil type, the slab should be 8’ to 12’ below ground level. Our design uses over 12,000 cubic feet of concrete which will produce over five million kgs of carbon emissions. However, due to the new materials we use on the exterior of the ATCT, this is the most significant source of carbon emissions. The steel used in the frame is the next highest source of carbon emissions. Beyond that, the construction of our design emits limited amounts of carbon.

The base is an elliptical shaft hosting an elevator and a staircase, built in a light-gauge steel framing system. The length of the shaft is adjusted based on the height needed for the control room operation placed between 60ft to 120ft at each site. The actual footprint of the tower is 322SF. The base is designed for an accessible walk-in after the security doors. The elevator and staircase are accessible from the lobby across from each other. The shaft is encircled by a curved hempcrete prefab panel. According to the study the exterior of our shaft will capture carbon. This prefabricated hempcrete is also used for insulation. Certain hempcrete bricks have an R-value 40 times higher than concrete. Hempcrete is a cheap form of insulation. Behind the wall, and adjacent to the elevator/staircase are two ducts for all the services such as electricity, HVAC, communication and plumbing.

This elliptical tower emerges into a square measuring 36ft on the side from the shaft. The square base hosts the required Ready/Break room, Mechanical room and Electrical and Equipment room. The lower floor is the Ready/Break room providing a restroom and kitchenette for the staff. This floor is supported by a steel floor and steel support beams that extend from the top of the steel shaft. This is the last floor with elevator access.

The upper level is a square floor plate measuring 39ft. This floor includes the mechanical room and electrical room. The Mechanical room provides HVAC service to the cab floor. The Electrical / Equipment room provides all the equipment storage needed for the cab floor. This floor is provided with the platform car lift to enable easy transfer for the equipment to the cab floor. The roof of the square base acts as the catwalk protected by railing.

Both the Ready/Break room and Mechanical room/Electrical room are built in a sustainable Algae Facade system. The algae façade system is made of a bioreactor system integrated between two glazing systems. This system has the advantages of excellent thermal insulation, noise protection, bioenergy production, and itself acts as a heating system for the structure. The capital cost for this facade is expensive, but its ability to capture carbon and produce biofuel that can supply the tower’s electricity and airport uses makes it efficient.

An octogonal cab floor is situated above the square floor plates. The Control Cab is built with structural glass and steel mullions with unobstructed views from double glazed windows. The windows can be washed and maintained by the catwalk that extends from the roof of the mechanical/electrical floor.

There is a latch in the ceiling that brings down a hidden ladder. From the ladder, one can access the roof which has a low gradient. The roof is surrounded by 4ft high walls extended from the control cab. With our first final design, we hoped to achieve an ATCT that’s LCA is minimum to promote sustainability at all levels of the US economy.

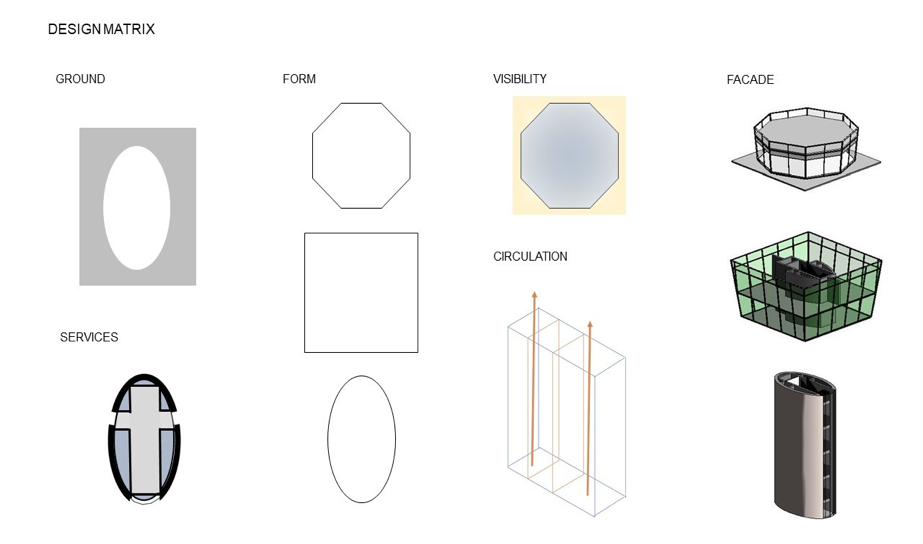

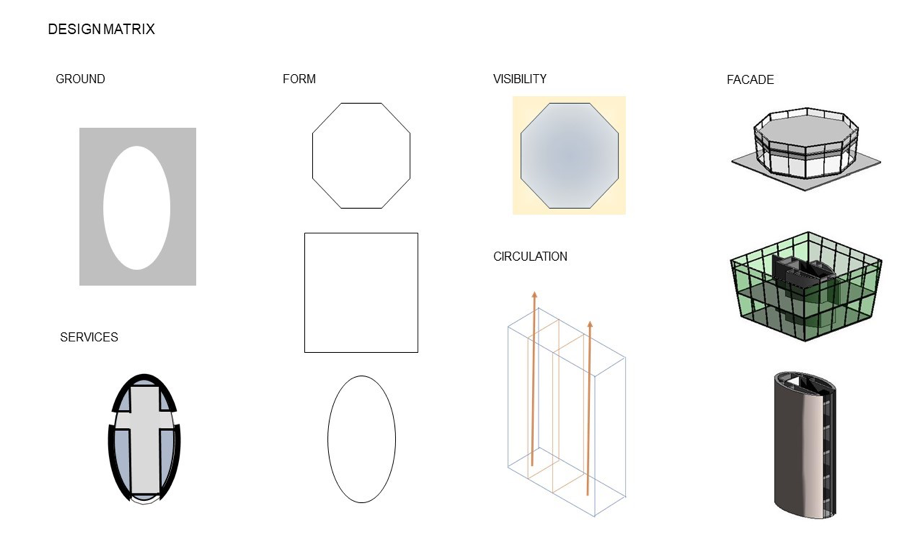

This design from Forever Flight Worldwide seeks to utilize groundbreaking materials such as an algae facade system and hempcrete to diminish the environmental impact and actually soak up carbon dioxide. Below are some simple draw ups of the design. The LCA of the project proves that our design is close to carbon negative post-construction.

Works Cited:

Biehl, Zoe. “The Amazing World of Hemp: Hempcrete - the Most Sustainable Building Material on Earth.” Cannabis Technology News, May 2019, https://www.cannabistech.com/articles/hemp-hempcrete-the-most-sustainable-building-material-on-Earth/.

DoD Releases Report on security implications of climate change," US Department of Defense, DOD News, July 29, 2015 www.defense.gov/newsarticle.aspx?id=129366

Hempcrete Natural Building, Hempcrete Natural Building, 2022, https://www.hempcrete.ca/.

“Industrial Hemp in the United States.” USDA Publications, USDA, https://www.ers.usda.gov/webdocs/publications/41740/15859_ages001ei_1_.pdf?v=

Kim, Kyoung-Hee. A Feasibility Study of an Algae Façade System. UNCC- School of Architecture, https://www.irbnet.de/daten/iconda/CIB_DC26782.pdf.

Komsi, Jere. “Thermal Properties of Hempcrete, a Case Study.” Theseus, Helsinki Metropolia University of Applied Sciences, 30 May 2018, https://www.theseus.fi/bitstream/handle/10024/149515/Komsi_Jere.pdf?isAllowed=y&sequence=1&utm_medium=website&utm_source=archdaily.com. McIntosh, Jerry E. “Soil Survey of Fulton County, Kentucky.” NRCS.USAD.gov, USDA, NRCS, https://www.nrcs.usda.gov/Internet/FSE_MANUSCRIPTS/kentucky/KY075/0/Fulton_KY.pdf.

Nyström, Sofia, et al. “REDUCING COSTS OF AIR TRAFFIC CONTROL, How Competition and Technology Can and Cannot Contribute to Reducing Costs of Air Traffic Control.” Copenhagen Economics, Copenhagen Economics A/S, 26 Mar. 2019, https://www.copenhageneconomics.com/dyn/resources/Publication/publicationPDF/6/486/1553615733/reducing-costs-of-air-traffic-control.pdf.

Roberts, Tobias. “Building with Hempcrete.” Rise, Rise, 6 June 2021, https://www.buildwithrise.com/stories/building-with-hempcrete.

“Sustainable Tower Design Initiative.” Federal Aviation Administration, FAA, 2021, https://www.faa.gov/tower-design.

Tan, Jaye. “Prefabricated Hempcrete Specification and Installation Manual 2015 ...” SlideShare, Studio Green Pte Ltd, 17 Nov. 2015, https://www.slideshare.net/JayeTan/prefabricated-hempcrete-specification-and-installation-manual-2015-by-studio-green-pte-ltd-55192539.

“The Amazing World of Hemp: Hempcrete - the Most Sustainable Building Material on Earth.” Cannabis Technology News, https://www.cannabistech.com/articles/hemp-hempcrete-the-most-sustainable-building-material-on-Earth/.

Wurm, Jan. “Glasfassadensystem Mit Integrierten Photobioreaktoren.” Bio-Energy Facade, Arup, https://www.arup.com/de-de/projects/bioenergy-facade.

Van Beek, Stephen D. “Remote Towers: A Better Future for America’s Small Airports.” Reason Foundation, Reason Foundation, https://reason.org/wp-content/uploads/2017/07/air_traffic_control_remote_towers-1.pdf.